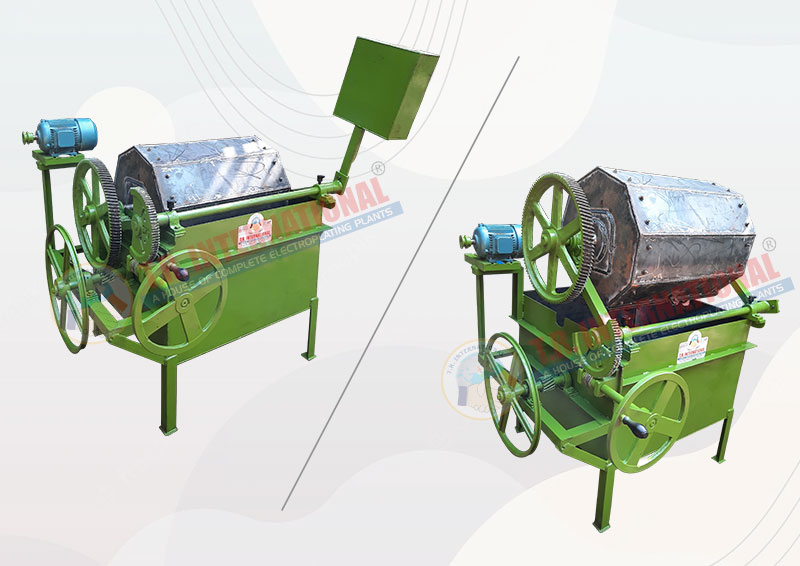

CAUSTIC BARREL

Know About Caustic Barrels

Electroplating has existed for quite a long time and advanced from being craftsmanship to a minor yet significant piece of science. Caustic Barrels are widely used in the process of Electroplating. It is likewise viewed as a feature of designing and has truly enlarging applications in various designing spaces.

In the most recent couple of years, the utilization of the electroplating cycle has expanded in assembling electrical or electronic segments, including optics, miniature, and large scale, sensors, and opto-gadgets. It stays the whole most significant cycle where gold plating or silver or other metal plating is concerned.

| Product Specification | |

|---|---|

| Material | MS |

| Brand | TR |

| Application | Electroplating Industry |

| Capacity | 100 to 120 kg |

| Origin Country | India |

Another Details About Product

Electroplating is otherwise called electrode position and is utilized for creating a metallic covering on the outside of an item using electric flow. The way toward Electroplating requires including a negative charge for the item to be plated and afterward drenching it in an ionic arrangement conveying a positive direction.

The emphatically charged particles are pulled into the opposing charged surface of the item, and in this manner, covering happens. There are so many Caustic Barrels Manufacturers in India that can offer caustic Barrels according to the needs of the Electroplating process.

Various Type Of Electroplating

Electroplating is utilized for covering any article with explicit metals, including gold, silver, nickel, chromium, and aluminum. There are four sorts of electroplating measures. The cycle to be utilized relies essentially upon the item to be covered, the properties to be improved, and the metal to cover. The various kinds of electroplating measures include:

Rack Plating

Barrel Plating

Mass Plating

About Rack Plating

Rack plating is an electroplating cycle performed utilizing a rack for holding the pieces of an article that should be plated. In rack plating, the workpiece or item is mounted on the rack and afterward submerged in the plating arrangement. It is otherwise called cluster plating.

Barrel Plating

Barrel plating is viewed as a conservative alternative to Electroplating and is utilized where clients have explicit plating prerequisites. Barrel plating obliges objects of various shapes and sizes for plating purposes. There are two distinct kinds of barrels used for plating – e even barrel and an angled barrel.

Mass Plating

Where little articles need to go through plating in massive or mass amounts, at that point, the mass plating measure is applied. This sort of electroplating measure can’t be utilized for sensitive items or workpieces. Mass planting can happen to use barrel plating strategies.

If you are looking for Caustic Barrels, contact TR International based in Punjab today. The company offers one of the best Caustic Barrels for Electroplating plants and is famous as one of India’s best Caustic Barrels Manufacturers.